Welcome to Heat Trace

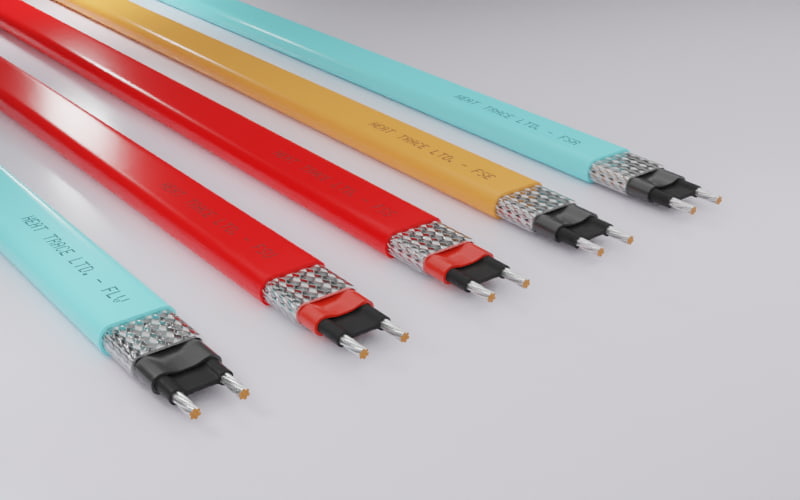

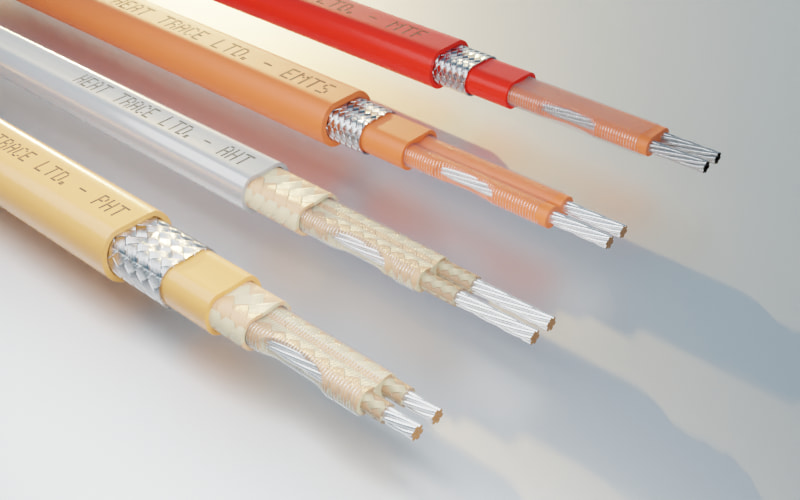

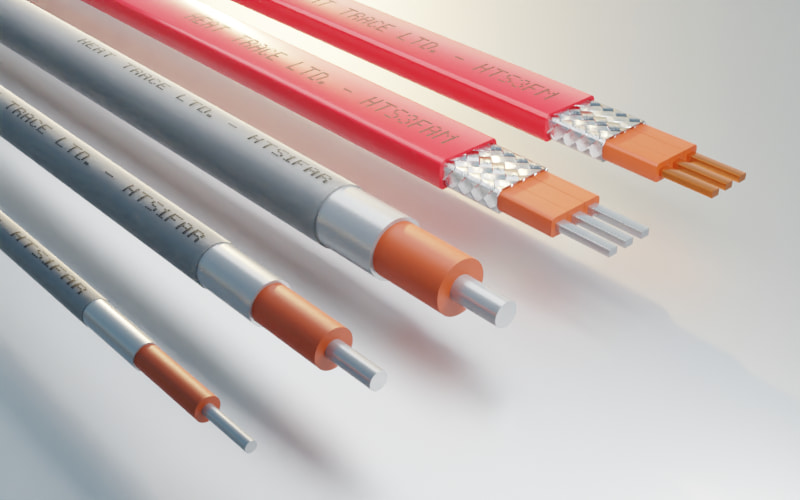

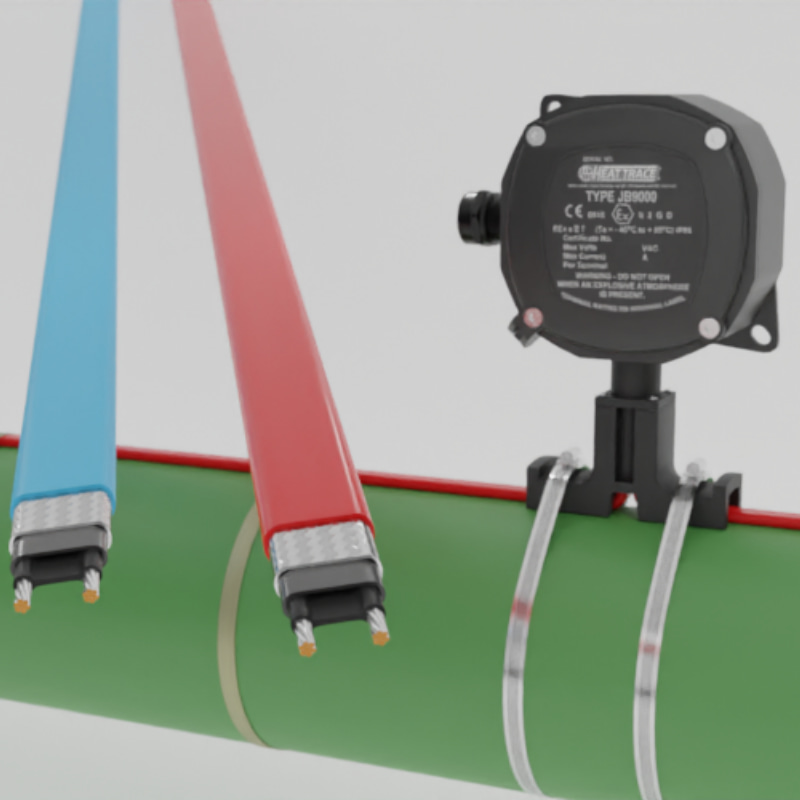

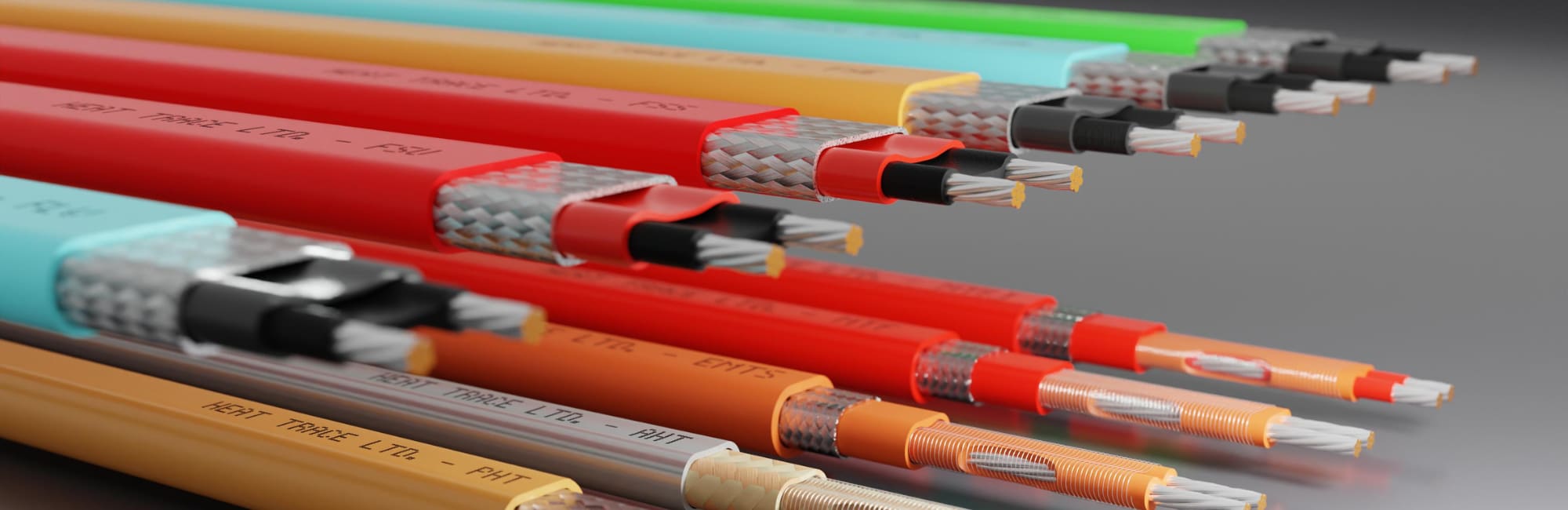

We manufacture the most technically advanced range of electric heat tracing equipment in the world

Established in 1974, Heat Trace Limited is now one of the world's leading suppliers of electric heat tracing equipment for both process temperature maintenance and freeze protection applications.

With offices, distributors or representation in over 50 countries, we can provide a variety of associated products and services to complement our heat tracing product range.

.jpg)

.jpg)

.jpg)