Tank Base Heating

The Problem

Natural gas has become increasingly important in recent years as a major energy source. The liquefaction of natural gas, whereby methane is cooled to approximately -160°C and liquefied, has provided tremendous opportunities. However, liquefied natural gas (LNG) production involves several highly complex steps, each presenting unique challenges for the engineers who design and build LNG facilities. Above all, safe and reliable operation is paramount and requires meticulous planning and execution by all involved.

The Solution

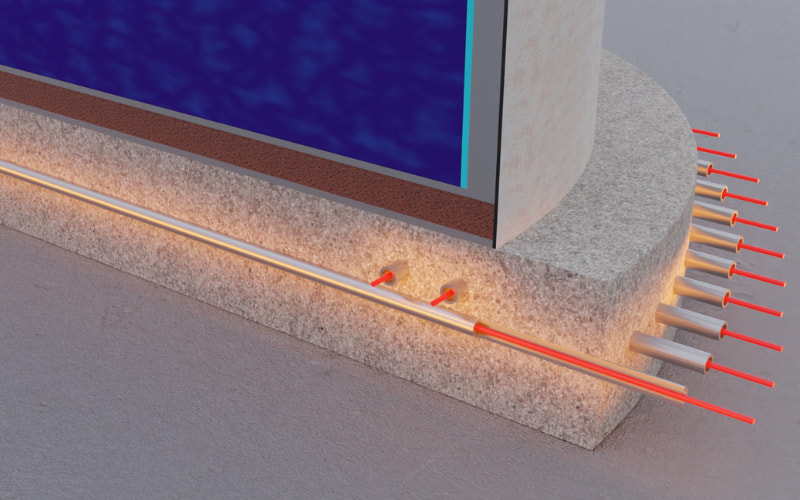

One critical safety consideration is the design of tanks used in LNG processing and storage. Proper tank design, especially the tank base, is crucial given the extremely low temperatures in LNG applications. Frost formation under tanks can cause cracks and deformation, damaging tank foundations. This phenomenon is often referred to as tank base heave protection.

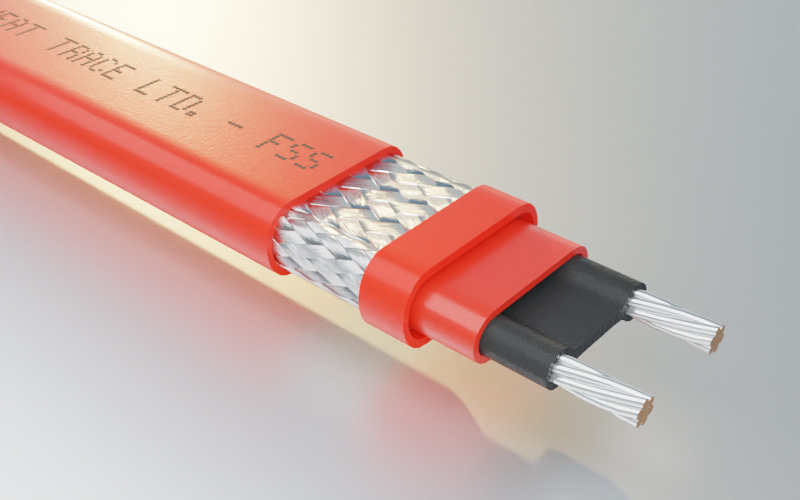

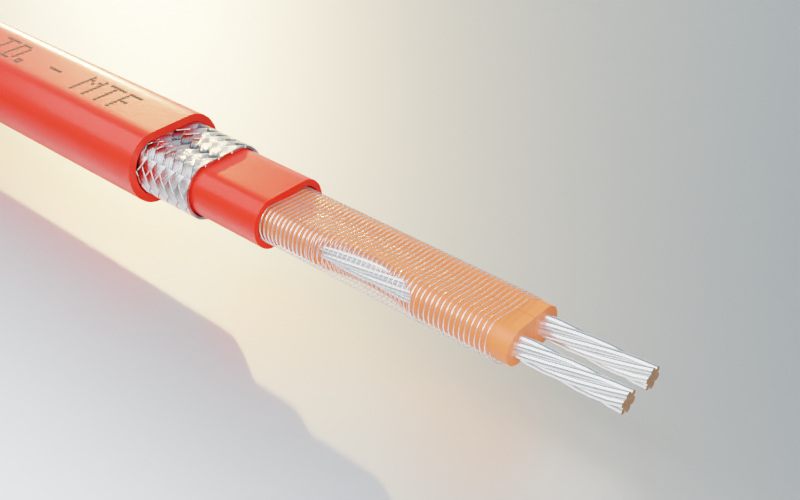

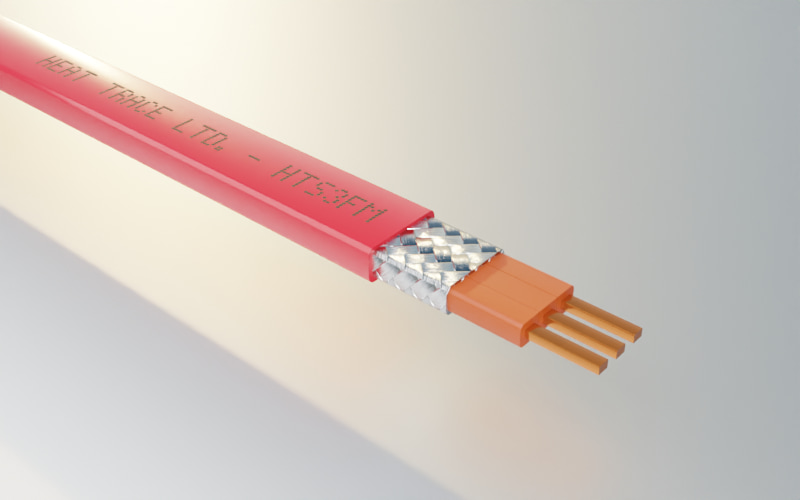

The most effective way to prevent this is by electrically heating the tank base. Experienced engineering is essential to avoid costly mistakes later. LNG storage tank foundations require heating systems that allow heat to flow up from the base, protecting it and the soil below from freezing. Typically, heating elements are arranged in parallel conduits in a horizontal plane with careful spacing calculations and Solidworks Simulation Finite Element Analysis simulation.

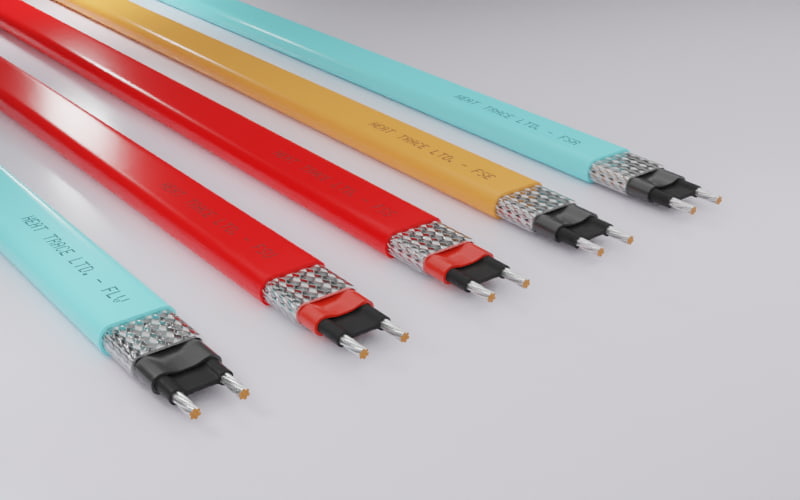

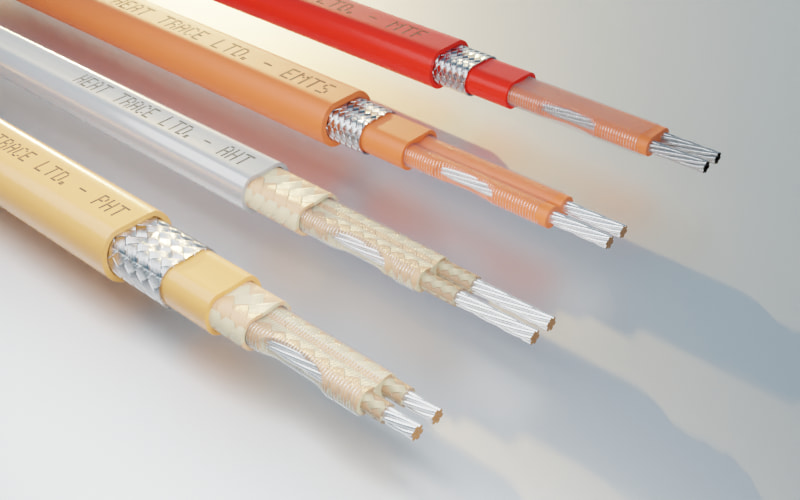

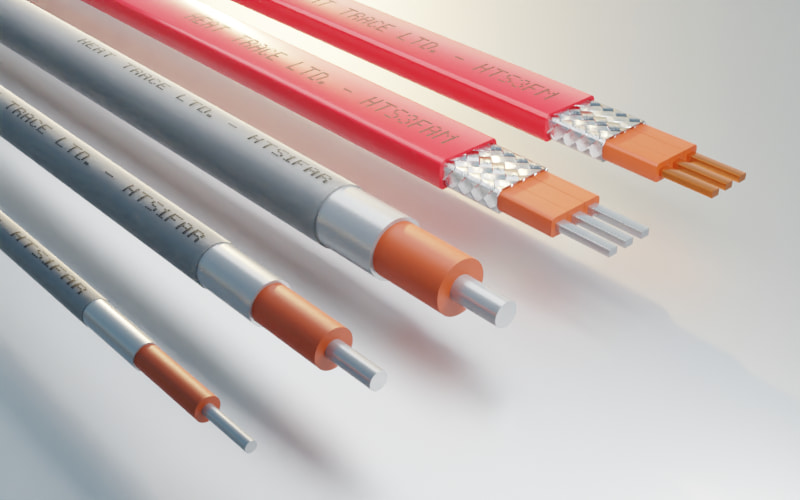

View the Heat Trace Cable Range Max Exposure Temperature & Output Capability Graph:

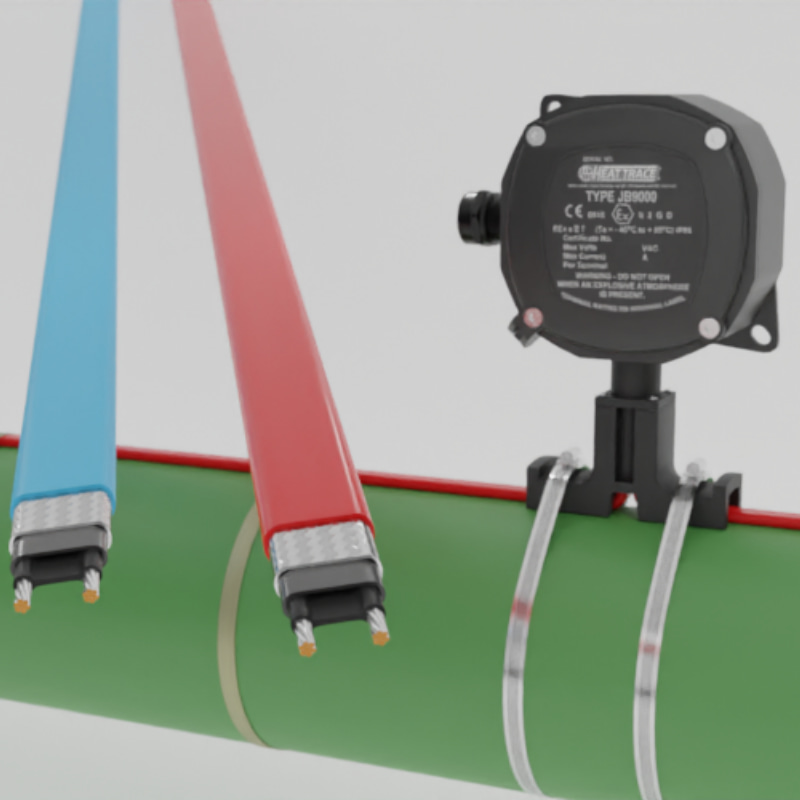

Control & Monitoring

Control most commonly comprises a simple ON/OFF air sensing thermostat (eg. Capstat or Durastat) acting through a load contactor if required, which fully powers the system at all times when the air temperature falls below a set point of say 4°C. The system may typically be energised for 2000 hours per year.

Circuit Health Monitoring

When self-regulating heaters are used, circuits may be monitored only for continuity. If monitoring for correct heating function is required, a constant power heater should be selected and used in conjunction with an automatic and continuous circuit health monitor and alarm (eg. Monitohm or Watchdog).