Instrument Pipes

Instrument and sample lines need to be maintained at optimum temperatures to ensure correct data analysis. During the design phase of the project, the actual lengths of the tubing are not known until the final installation (site run tubing).

For low temperature applications this is not a large concern, but when the tubes can experience temperatures over 250°C (e.g. high pressure steam) then the majority of self-regulating cables will be damaged.

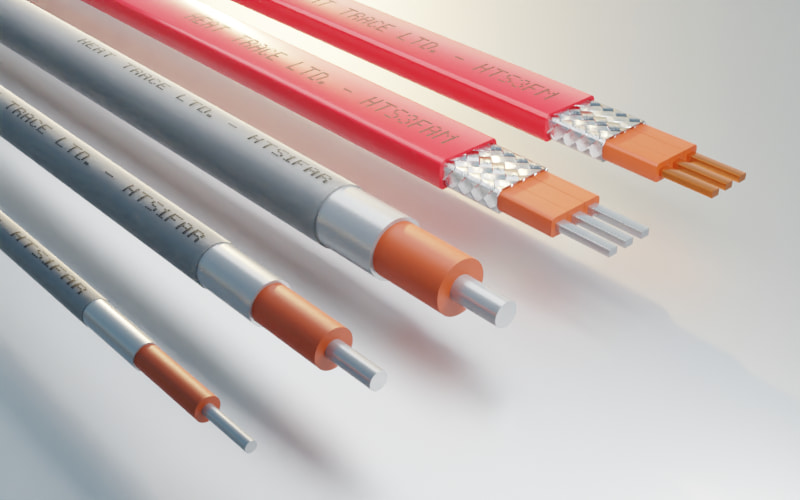

Typically over this temperature, Mineral Insulated (MI) cables are used, but since the tubes are normally site run this can be very difficult as MI cables are pre-terminated off site and can't be changed on site.

Site run tubing determines the length of the heating cable

The Solution

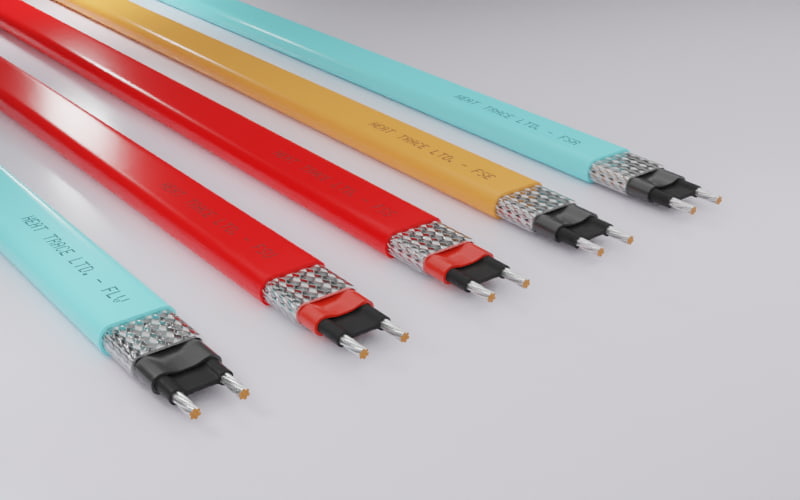

For maintain and exposure temperatures below 250°C, Heat Trace have many self-regulating products that can be used just as they would on any other pipeline or equipment.

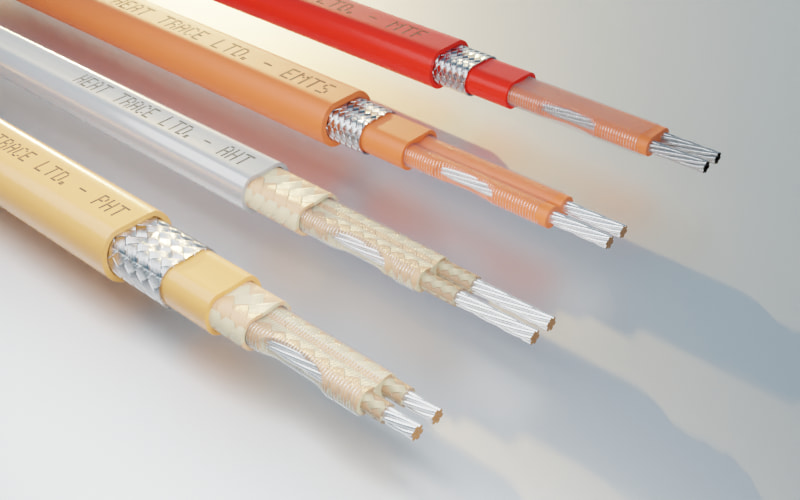

For temperatures exceeding that, (up to 500°C exposure), Heat Trace have our parallel constant wattage heating cable range AHT.

AHT is a high temperature heating cable, capable of being exposed up to 500 °C (350 °C energised) without being damaged. Since the AHT cable can be cut to length at site due to its parallel circuitry.

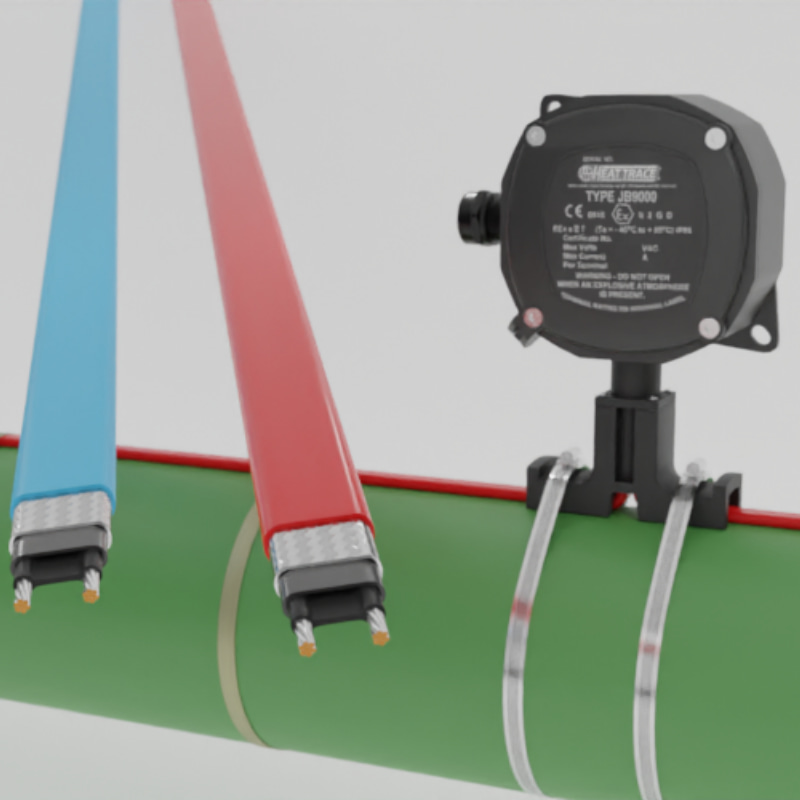

Another advantage is that constant wattage heating tapes can be joined using either a jointing kit or a trace heating junction box.

This now solves the problem of site run tubing as the cable can be cut to match the exact site run route.

A further advantage is that MI cables can take multiple weeks to manufacture and deliver to site once the route is confirmed. In very rare instances, the MI cables are manufactured on-site, but this requires a full workshop to be available on site with skilled welders, etc. AHT Cable can be kept on a reel in a warehouse and the exact lengths can be installed right at the tubing location with regular tools.

Short circuit lengths are also very important when comparing AHT and MI cables. For very short MI circuits, the heating circuit will either need to be fed with a lower voltage than what is available (requiring a custom transformer) or multiple MI cables will have to be connected in series to increase the overall reistance to be able to match the available site voltage (e.g. 230V). The problem with the latter approach is both control and the fact that if a single MI cable fails, the whole circuit will de-energise and many instrument lines will be without heat.

With AHT cables, the minimum circuit length is only 1m and this will still operate at the site voltage (e.g. 230V). This prevents having to group multiple instrument lines onto a single circuit.

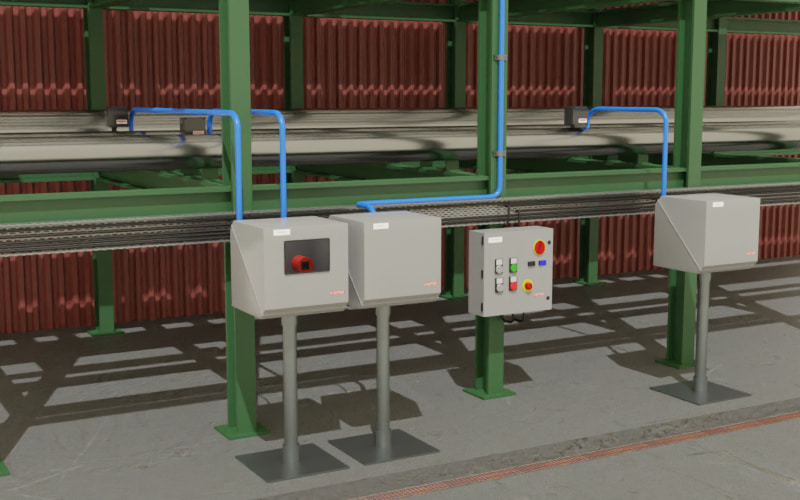

Instrumental Heating

Our full range of heating cables can also be used for freeze protection or temperature maintenance on vessel level gauges, pressure gauges, etc. The flexible nature of our cables means that even complex instruments can be fully protected.

View the Heat Trace Cable Range Max Exposure Temperature & Output Capability Graph: