About

When Heat Trace was founded by Neil Malone in 1974, Electric Heat Tracing was still in it's formative years. In the five decades since, it has developed into a significant industry based on quality principles.

Throughout this time, Heat Trace Limited has been at the forefront of the heat tracing industry, deeply involved in the development of standards, from BS6351 - Electric Surface Heating, the first British standard published in 1982, through to IEC60079/30 – a harmonised World Standard first launched in 2001.

From the start, Heat Trace developed products and systems not only satisfying the new standards, but also meeting Heat Trace’s own corporate objectives of improving . . .

Safety, efficiency, performance and life

These highly focused objectives engendered a corporate culture within the company that remains to this day. The result has been a stream of novel, patented products – both heating cables and control and monitoring equipment – that have seriously influenced the direction and focus of the heat tracing industry.

Today Heat Trace Limited is a global company providing complete heat tracing solutions. In addition to systems manufacture, services include consultancy, system design, commissioning, project management and research & development.

A Quality Company

Heat Trace is an ISO9001:2015 accredited company for manufacturing, system design, engineering and product development. Our first quality certification was issued on 4th October 1991 and has been updated and re-assessed over the years. This has lead to a finely tuned and ideally suited quality management system for a leading global manufacturer.

It is the stated quality policy of Heat Trace to satisfy the requirements of our customers. This can only be achieved by operating a comprehensive, co-ordinated quality system that assures the quality of all products, processes and services offered by the company.

This system has been re-designed and updated to meet the requirements of ISO 9001:2015 and is implemented across the whole organisation, embracing all of the activities which impact upon our customers.

The directors of the company are committed to ensuring that the system is effective in achieving quality and satisfying customers both now and in the future.

In September 2002 HTL Quality Systems demonstrated compliance with the ATEX Directive 94/9/EC, therefore enabling the company to sell certified products for use in Hazardous Locations and Explosive Atmospheres in Europe.

The Quality Systems were enhanced when in May 2011 HTL successfully gained the world wide IECEx Quality Assessment Report, bringing the company up to date with quality system accreditation, at that time.

Heat Trace's quality portfolio has been further extended by the addition of the new UK QAN in October 2021, allowing Ex products to be certified and sold under the new UK Explosion proof scheme into our home market with the advent of Brexit.

We will strive to continually improve our products, processes and systems by setting quality objectives that are measurable and are reviewed.

Production Facilities

Heat Trace, Helsby

.jpg)

Heat Trace, Bredbury

.jpg)

Heat Trace, Southside

Heat Trace has been manufacturing electrical heating cable in the U.K. for over 50 years.

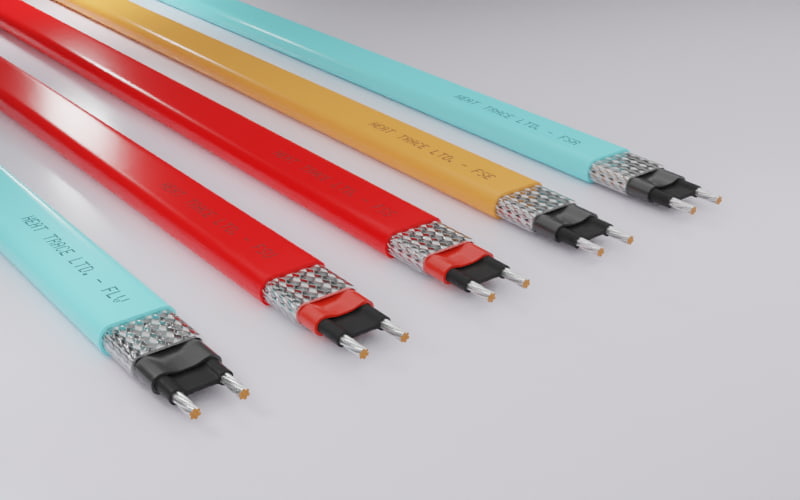

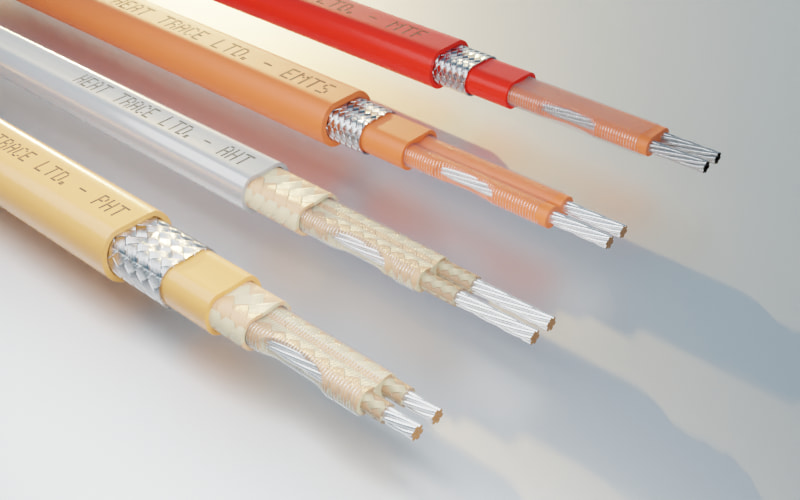

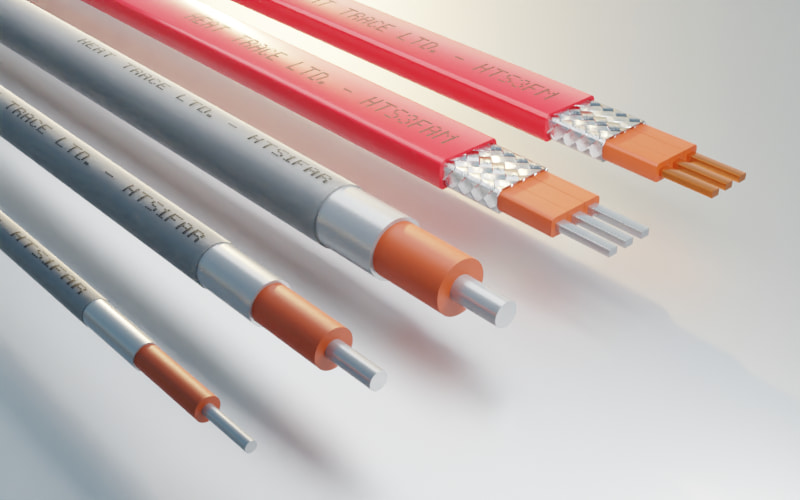

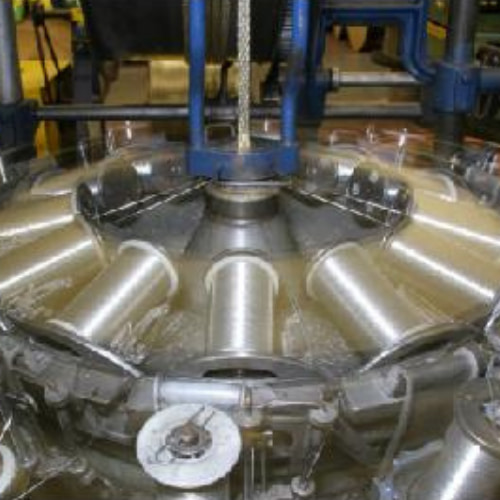

The main manufacturing facility and headquarters of the company are at Helsby in the North West of England. This factory houses all the processing equipment for the manufacture of semi-conductive self-regulating heating cables, core compounding, heating matrix extrusion and insulation. The main item of capital equipment is the Electron Beam Unit - one of only a few similar units in the U.K.

A second manufacturing facility is located in Bredbury, Stockport some 56km from Helsby. The Bredbury site has been owned by Heat Trace for 20 years and constant power heating cables are made there.

Heating Core Extrusion

Electron Beam Unit

Insulation Extrusion

Braiding