Freeze Protection

The Problem

In cold climates, water or chemical pipework often needs to be heat traced to prevent freezing. Thermal insulation alone is incapable of preventing freezing. A 25mm bore pipe at 5°C having 25mm thick insulation will reach freezing point within one hour in an ambient temperature of -10°C.

Steam at, say 150°C, is not a viable fuel source for simple freeze protection and of course, condensate returns may themselves freeze. Electric heat tracing having a low power output is the most convenient and efficient option.

The type of control system will determine operating costs.

The Solution

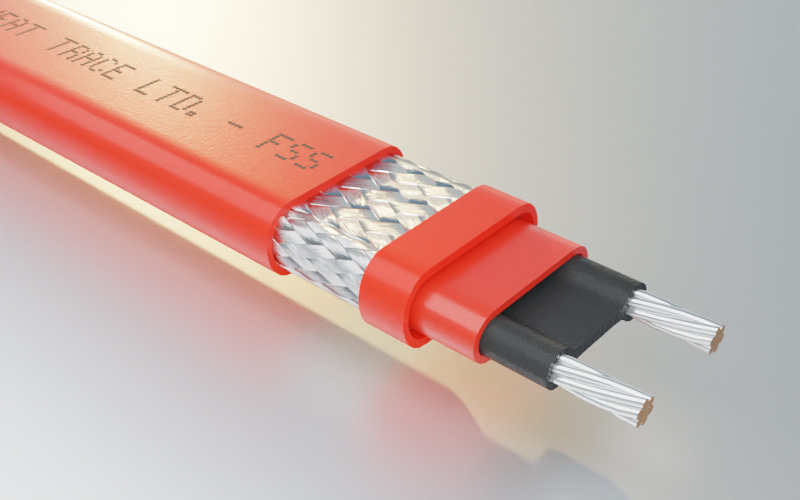

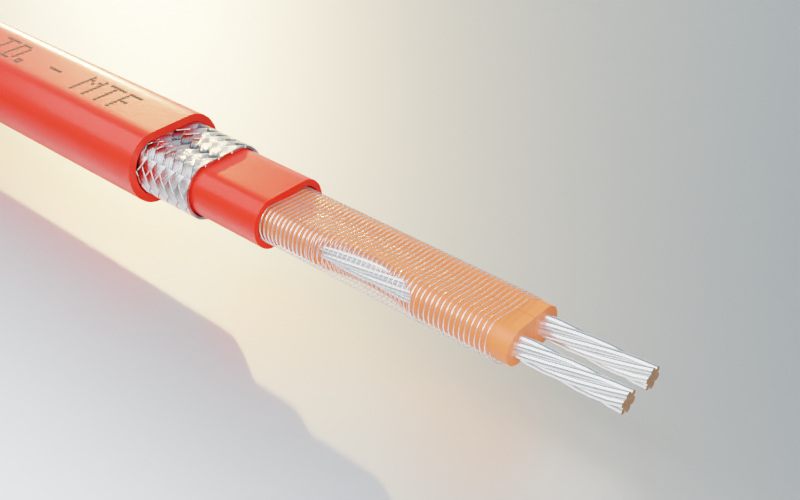

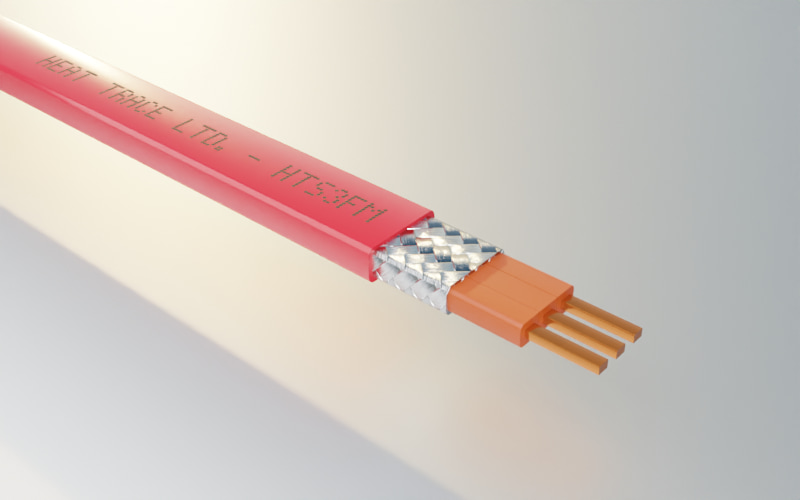

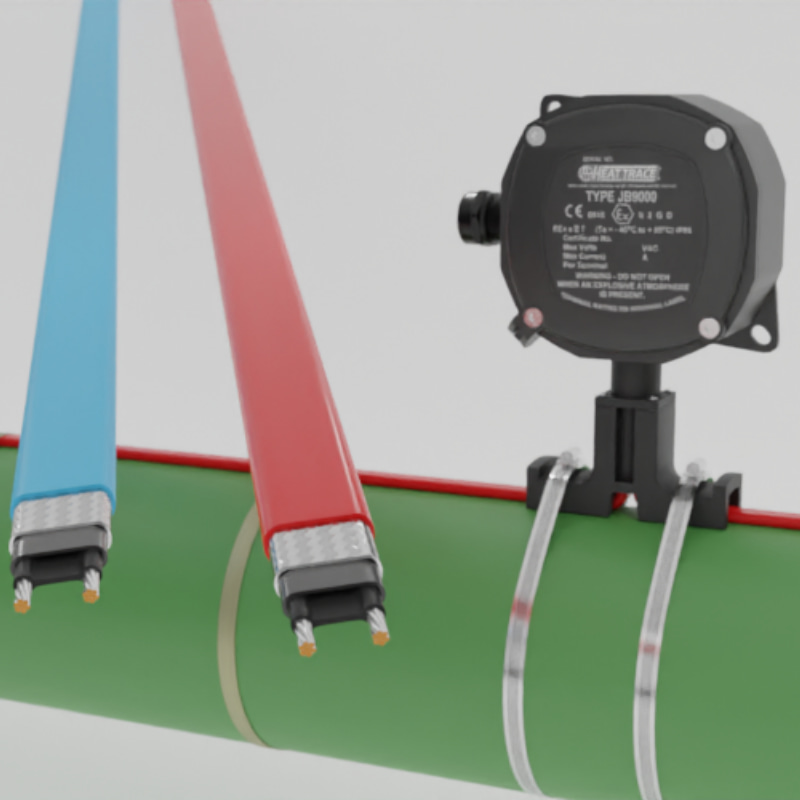

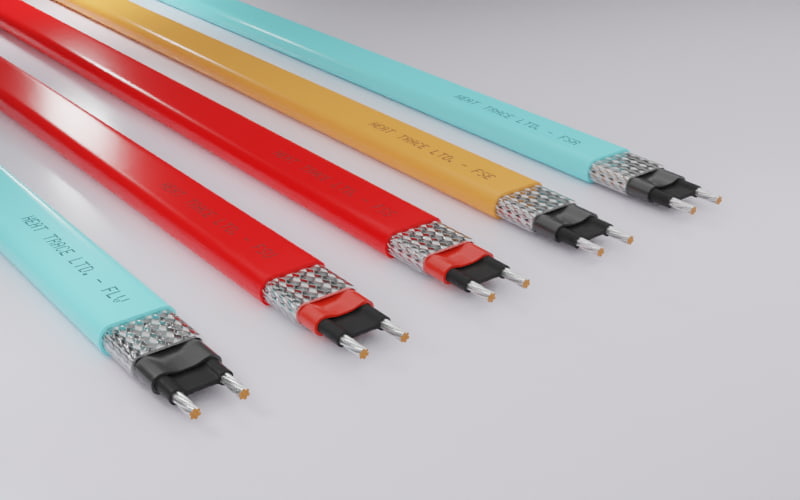

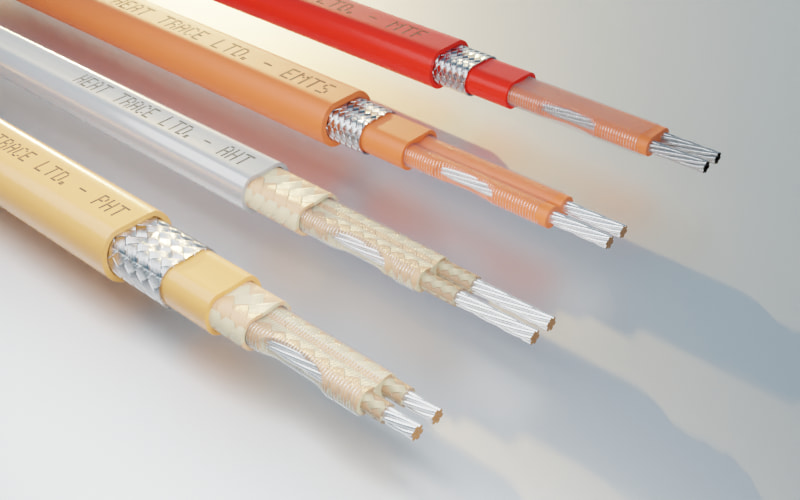

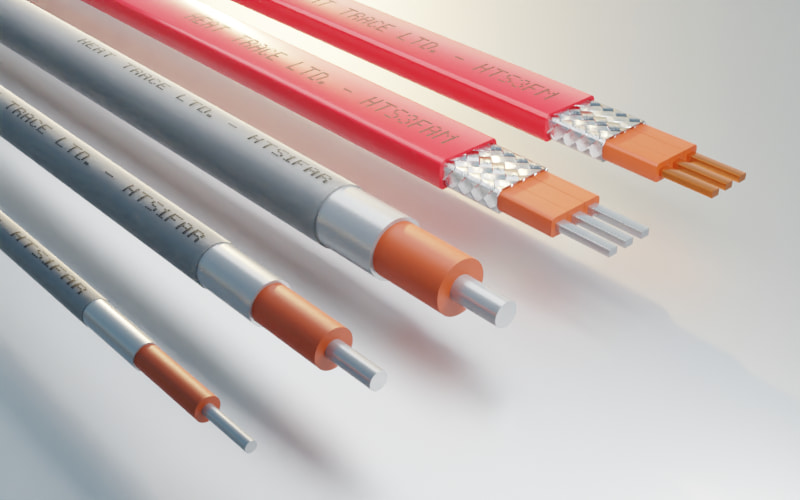

For installations of less than 500m of pipework, parallel resistance self regulating (eg.Freezstop Regular) or constant power heating cables (eg. MiniTracer) are chosen which can be cut to length when required on site. When longer circuit lengths are required, series resistance cables can be used (eg. Longline).

View the Heat Trace Cable Range Max Exposure Temperature & Output Capability Graph:

Control & Monitoring

Control most commonly comprises a simple ON/OFF air sensing thermostat (eg. Capstat or Durastat) acting through a load contactor if required, which fully powers the system at all times when the air temperature falls below a set point of say 4°C. The system may typically be energised for 2000 hours per year.

Circuit Health Monitoring

When self-regulating heaters are used, circuits may be monitored only for continuity. If monitoring for correct heating function is required, a constant power heater should be selected and used in conjunction with an automatic and continuous circuit health monitor and alarm (eg. Monitohm or Watchdog).