Published date:

Industrial Heating Winter Checklist

Whilst cold temperatures are expected during the winter months, protecting your industrial facility has never been more important with the increase of costs and energy.

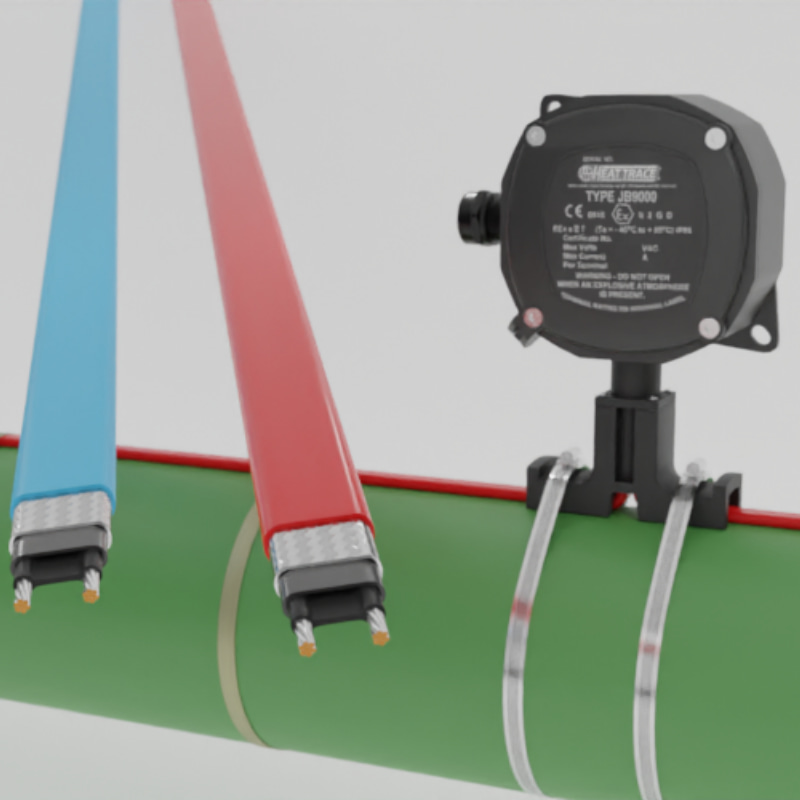

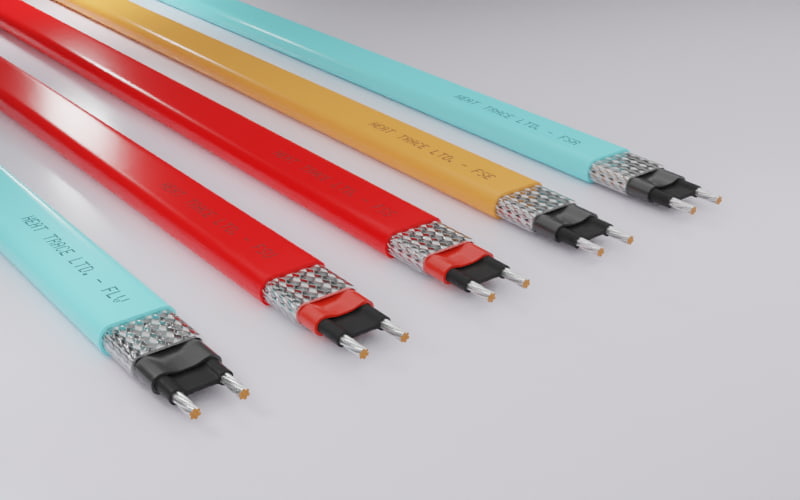

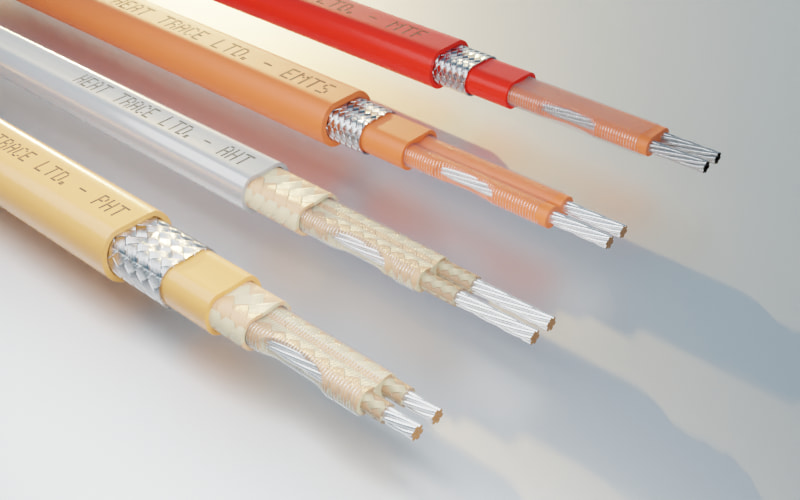

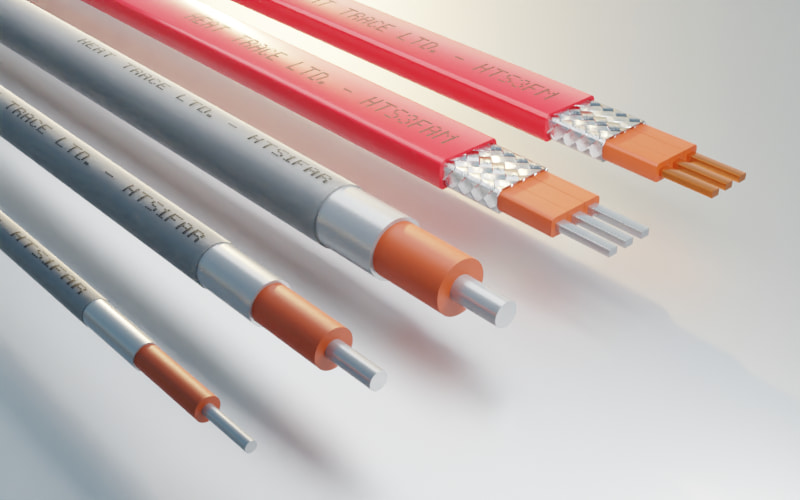

Protecting your plant with an electrical trace heating system is an energy efficient solution which will last for years to come, reducing downtime and loss of production. Electrical heat tracing systems keep pipes and pumps flowing and prevents associated equipment from freezing, providing protection no matter where pipes are; above or below ground, inside or outside.

These systems can be effective in; freeze protection of pipes, process temperature maintenance, roof and gutter de-icing and snow and ice prevention.

Here’s our checklist to protect your plant this winter:

- Perform audits, to identify possibly issues and allow them to be rectified early or prevented all together.

- Check existing trace heating for damage and that it is properly installed – this can prevent corrosion, water ingress and the loosening of electrical connections from going undetected.

- Optimise your energy usage using thermostats and controllers.

- Check insulation, as wet insulation or a lack of insulation can mean your electrical trace heating will be completely ineffective.

- Test the elements of your system; test the insulation resistance on all heat tracing circuits and also test all ground fault breakers and power supplies.

Get in touch with our team today to find out how we can help your business.