Published date:

Electric Heat Tracing of Very Long Pipelines

Heat Trace Ltd. has been active in Longline heating cables since 1985. Heat Trace designed and supervised the very first pre-insulated pipe that was installed in New Zealand.

What is the Definition of a Very Long Pipeline?

Historically, a long pipeline was anything greater than 1000m. At that time, this was potentially the furthest a very low output Mineral Insulated (MI) cable could reach under perfect conditions. Pipelines longer than that would require multiple circuits along the route of the line.

.jpg)

In the years to follow, those distances have steadily increased to the point where the current* longest electrically heated pipeline is approximately 670km in length. At that time (2010), this pipeline utilised Skin Effect heating and the approximate maximum circuit lengths were in the region of 18km. * - at time of writing 2016.

In the present day, the lengths of pipelines being discussed and currently in FEED stage by Oil owners and interested parties, is in the region of 2000km. As you can see, the need to reach farther from a single power point has become very important.

Heat Trace Ltd. has been active in Longline heating cables since 1985. Heat Trace designed and supervised the very first pre-insulated pipe that was installed in New Zealand. This line used Series Resistance heating cables and it was the very first in the world utilising pre-insulated pipe with a channel incorporated to allow installation of our heating cable.

There are various types of heating technologies available which we will discuss and show you the potential benefits and downfalls of each technology

What Voltages are involved?

Voltages in the past were limited by the Heat Tracing Standards which typically kept those voltages at, or below, 600V. The limitations of these voltages were also the limiting factor of the maximum lengths we could push.

As the Standards were polished and adjusted over the years, these restrictions were removed and now we can use almost any voltage we would like (within reason).

Currently, Heat Trace have cables suitable for operating up to 6.6kV.

Heating Technologies

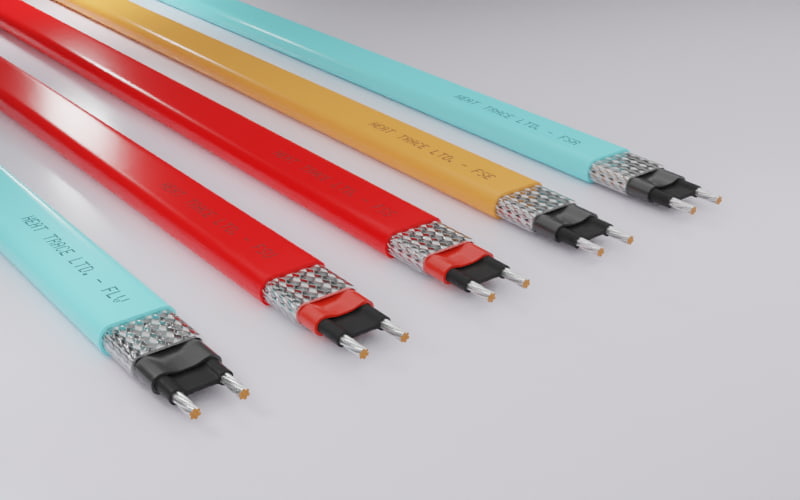

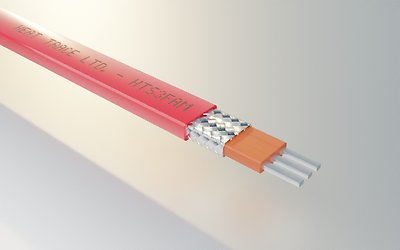

Longline Flat 3 Foil Cables

The first Series Resistance heating cables utilised standard round copper wires, insulated as a single flat style cable. These cables had a fair reach of around 1km, but isn’t wasn’t far enough for current projects.

Heat Trace developed a flat foil technology, which allowed much larger conductors to be placed into the heating cable. Instead of being stranded conductors, Heat Trace uses solid conductors.

These conductors are insulated sufficient to allow us to connect voltages up to 600V allowing for distances up to 8km.

This cable is exactly the type of cable that was installed on the World’s first reeled sub-sea electrically heat traced, pipe-in-pipe system in association with Technip and for Total.

Current developments are extending this distance to 10-12km.

With these cables, the conductors are connected to each phase of a transformer and the remote end conductors are simply star connected together, creating your complete circuit.

Circuit Reach per Cable

Maximum: ~8km (with potential for 12km)

Average: ~6km

Pro’s

- Very easy to install. Simply tapes to the pipe or pulled through a pre-insulated channel

- Outputs of up to 50 W/m

- Inline equipment can be heated and the cable removed for maintenance

- No damage to any corrosion layers

- Leaves the pipe flexible if required (e.g. for reeled installation sub-sea)

- Over 99% efficient as the phases are 100% resistive and completely balanced

- Flat profile provides very efficient heat transfer

Con’s

- Limited maximum reach

- Limited maximum voltage

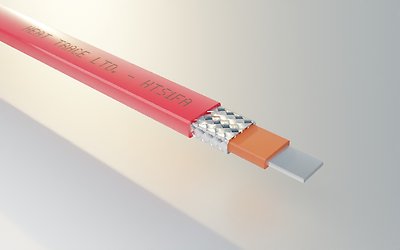

Longline Flat 1 Foil Cables

As mentioned, the requirements to reach further and further distances have become important over that last number of decades. To do that we needed to both increase the voltage and also the conductor size. To do this with a 3 foil cable would make it too large to easily install and a logistical nightmare to transport at any reasonable length.

We took the 3 foil cable and separated those conductors into their own cable. The cables now are sufficient to allow us to connect voltages up to 1000V allowing for much longer distances.

With these cables, three cables are now required for a single circuit. As before, each conductor is connected to each phase of a transformer and the remote end conductors are simply star connected together, creating your complete circuit.

Circuit Reach per Cable

Maximum: ~50km

Average: ~40km

Pro’s

- Very easy to install. Simply tapes to the pipe or pulled through a pre-insulated channel

- Outputs of up to 50 W/m per cable (150 W/m per circuit)

- Inline equipment can be heated and the cable removed for maintenance

- No damage to any corrosion layers

- Leaves the pipe flexible if required (e.g. for reeled installation sub-sea)

- Over 99% efficient as the phases are 100% resistive and completely balanced

- Flat profile provides very efficient heat transfer

Con’s

- Needs 3 cables per circuit

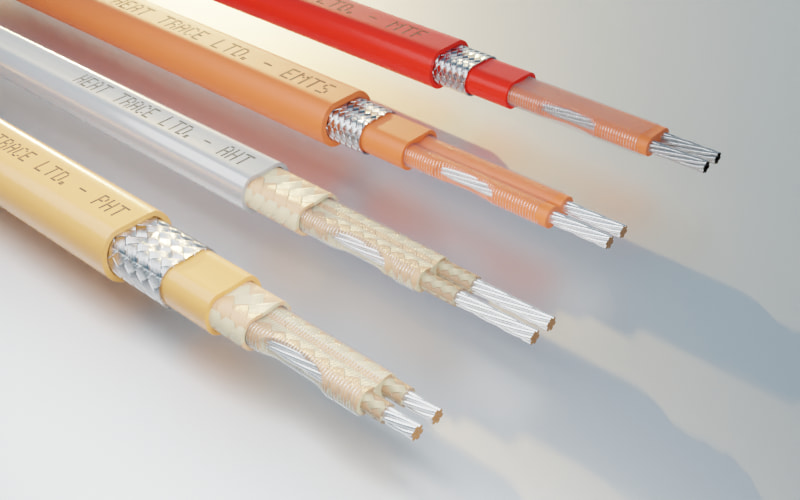

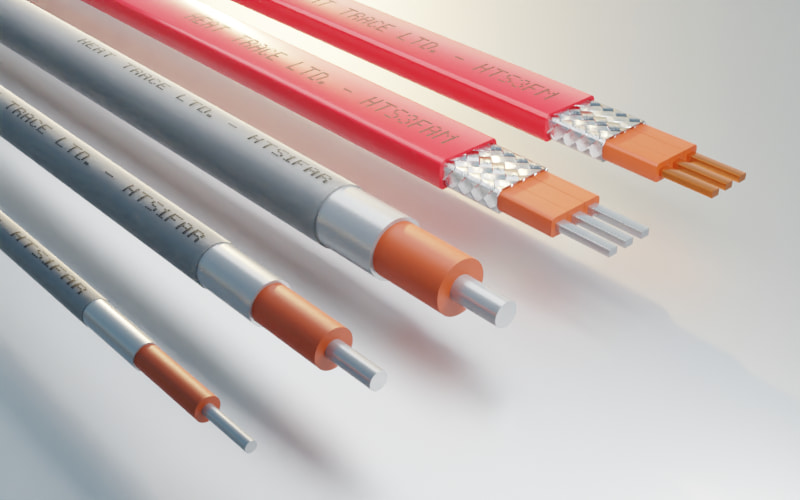

Longline Round 1 Foil Cables

Flat cables are very versatile and certainly a good candidate for longline applications. However, to go even further we would have to increase the insulation size which would a) make the cables more expensive, b) make the cables heavier and c) more difficult to install. This partially due to insulation resistance and a phenomena named partial discharge (PD). This PD creates arcs within the insulation and earth path and eventually degrades the insulation.

To overcome this, you can make the cable round. This removes the sharp edges as shown on the flat cables and removes this area where PD occurs.

The cables now are sufficient to allow us to connect voltages up to 6600V allowing for even longer distances.

As before, each conductor is connected to each phase of a transformer and the remote end conductors are simply star connected together, creating your complete circuit.

It must be noted that we can finish this cable in many ways (e.g. aluminium sheath as shown, copper braid with a PVDF or other finish).

Circuit Reach per Cable

Maximum: ~60km

Average: ~50km

Pro’s

- Very easy to install. Simply tapes to the pipe or pulled through a pre-insulated channel

- Outputs of up to 50 W/m per cable (150 W/m per circuit)

- Inline equipment can be heated and the cable removed for maintenance

- No damage to any corrosion layers

- Leaves the pipe flexible if required (e.g. for reeled installation sub-sea)

- Over 99% efficient as the phases are 100% resistive and completely balanced

- Flat profile provides very efficient heat transfer

Con’s

- Needs 3 cables per circuit