Published date:

Heat Trace - 'Going the Distance'

Over 30 years ago Heat Trace Ltd. installed the first buried longline system using longline heating technology in preinsulated piping based in New Zealand. Since that project, the requirements to push the distance the longline heaters can go are continually being extended. Initially circuit lengths were limited to 1-2 kms.

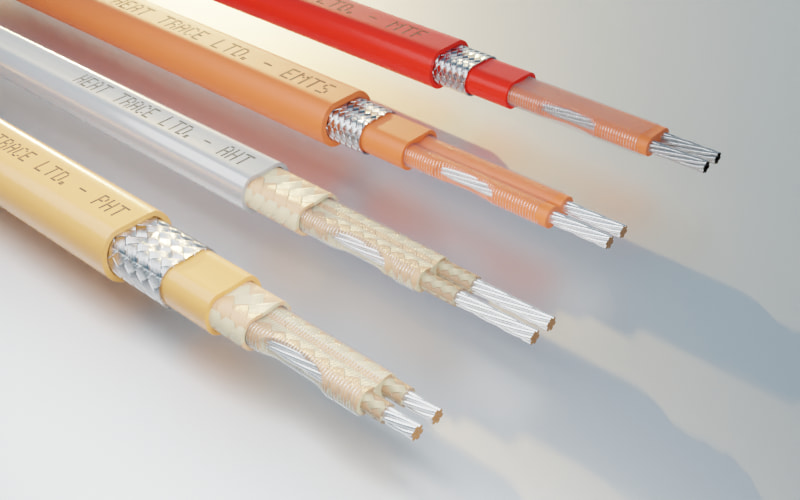

LLR cables to the left & typical LLR-HV cables arranged in channels to the right

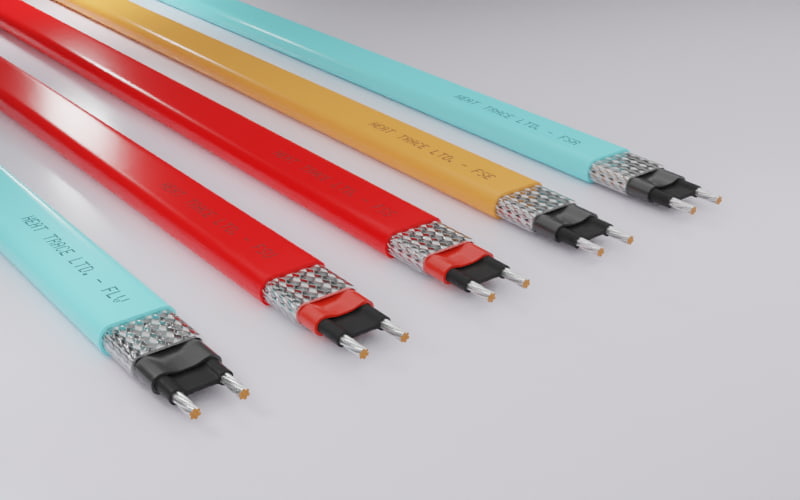

To extend the length of the circuits, higher voltages and larger cables were required. A decision was made some time ago to separate the 3 flat conductor series resistance cables into separate single flat foils which allowed us to increase the cross sectional area of the cables, thereby lowering the resistance of the cable and extending the length of the heater circuits to approximately 6-8km.

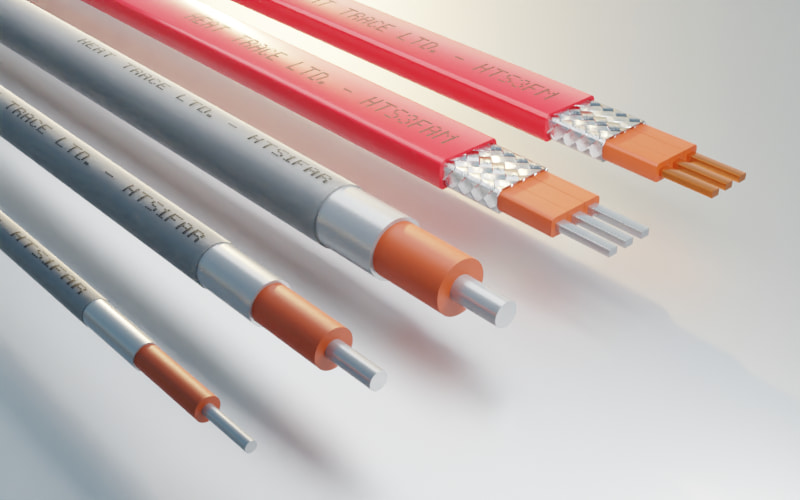

Recently we have developed a round series conductor cable with increased insulation thickness to allow the voltages to be pushed even higher. We also are manufacturing these heater cables with aluminium conductors (as opposed to copper). This has a major cost saving impact and the other noticeable saving is the weight of the finished product. This is a vital requirement for offshore oil drilling platforms for example, where weight saving is strongly optimised.

The new cables are split into two families; LLR and LLR-HV.

LLR is designed to work up to 100V and LLR-HV is currently designed to work up to 5 kV (with a final goal of 6.6 kV).

The distances for LLR is approximately 1000-1500m and LLR-HV with distances up to 40-50km from a single power point. If this is centre fed we can expect a single power point to reach distances of around 100km.

Cable conductor diameters are as follows;

LLR

• LLR-1.5A – 1.5mm OD

• LLR-2A – 2mm OD

• LLR-3A – 3mm OD

• LLR-4A – 4mm OD

• LLR-5A – 5mm OD

• LLR-6A – 6mm OD

LLR-HV

• LLR-7A – 7mm OD

• LLR-9A – 9mm OD