Hangar Door Heating

The Problem

For facilities located in cold climates, unheated hangar door rails can accumulate ice during frigid temperatures, impeding the doors' ability to open and close properly. To address this issue, our heating cables can provide an effective rail de-icing system that prevents ice buildup on hangar door rails, enabling the doors to function reliably even in harsh winter conditions.

.jpg)

The Solution

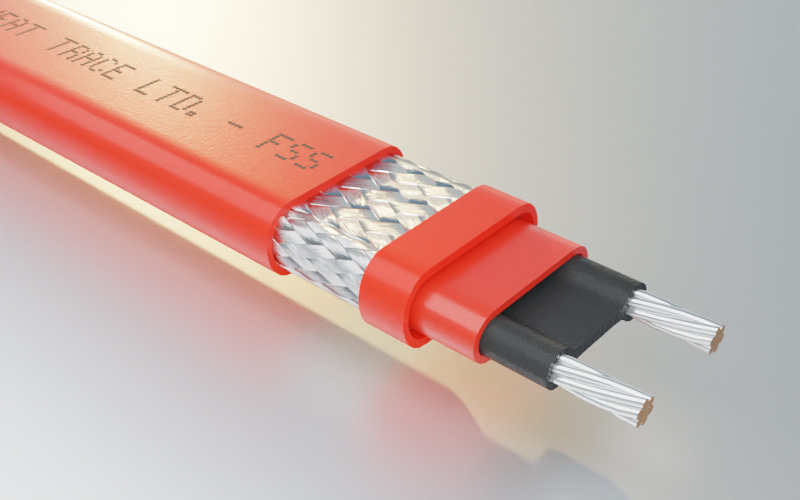

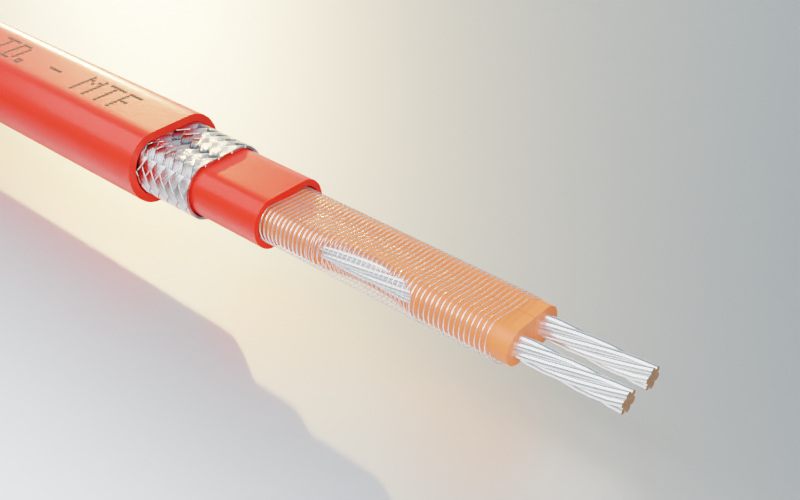

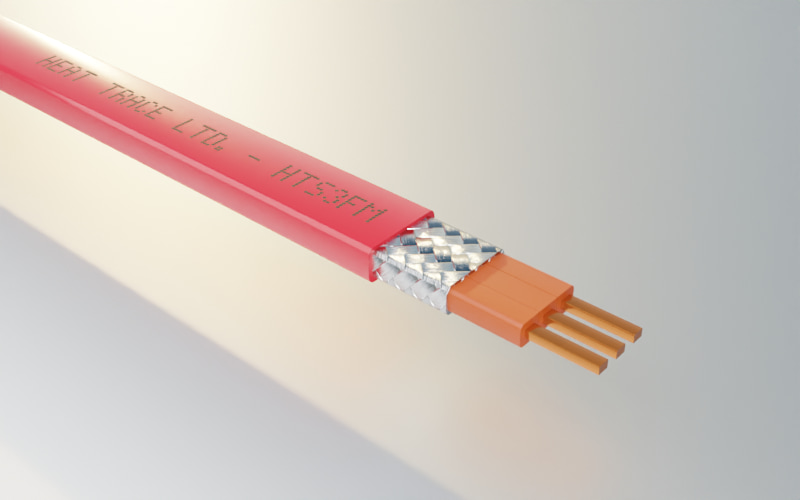

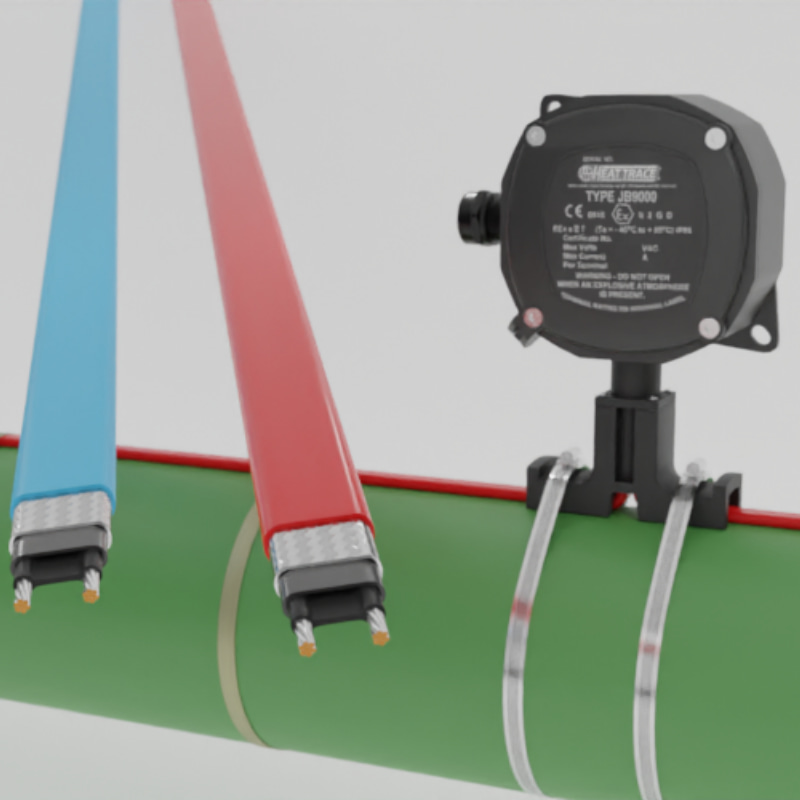

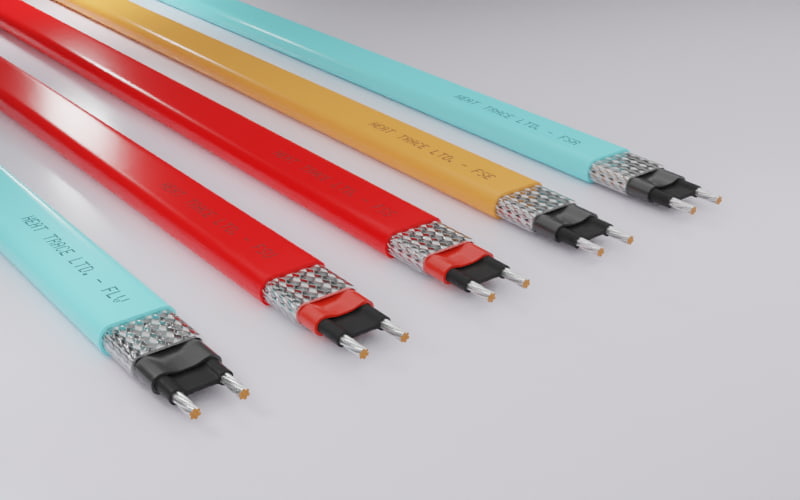

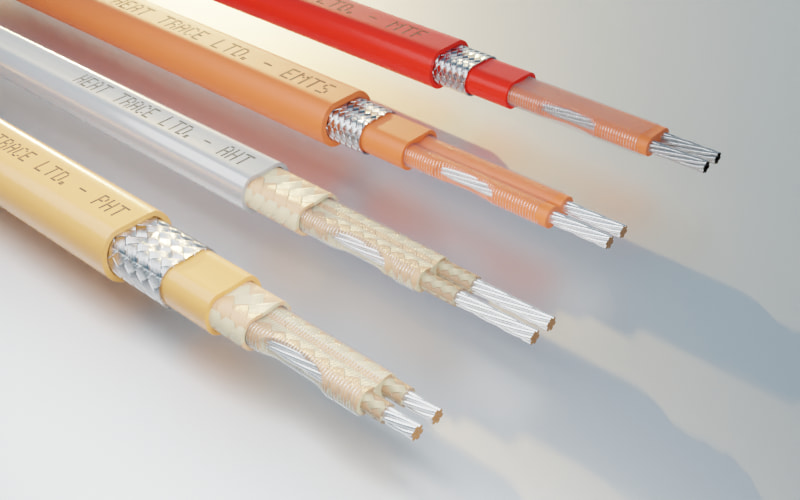

The system utilizes self-regulating/constant wattage heating cables installed on each side of the bottom door rails, which apply sufficient warmth to prevent moisture from freezing on the rails' surfaces. By keeping the rails free of ice and snow accumulation, the doors are able to roll unhindered across them, facilitating smooth opening and closing.

Additionally, rigid steel conduits can optionally be installed parallel to each rail to simplify maintenance and replacement of the heaters, if needed.

Outdoor sensors monitor ambient temperature and precipitation levels, signalling a controller to activate the rail de-icing system automatically when conditions warrant. The system is designed to switch on only as required and deactivate when the inclement weather has passed.

In summary, our thoughtfully engineered hangar door rail de-icing system offers an effective solution to ensure hangar doors remain functional during winter's freezing temperatures and storm conditions. Please contact our team to learn more about this reliable product offering.

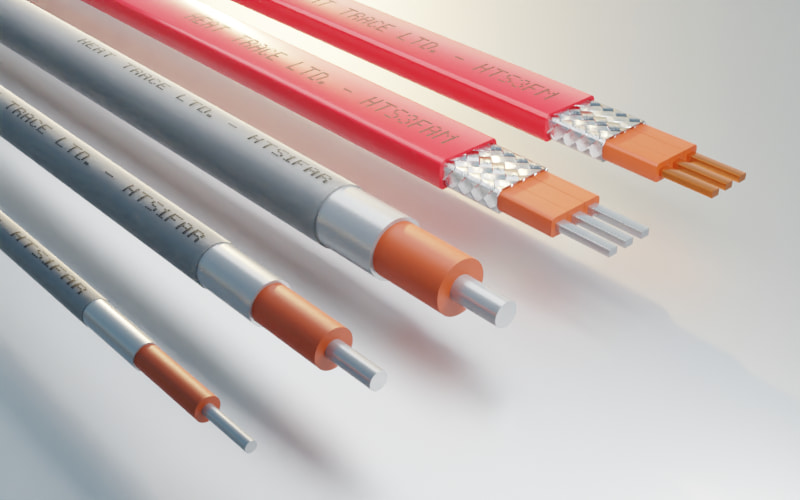

View the Heat Trace Cable Range Max Exposure Temperature & Output Capability Graph:

Control & Monitoring

Control most commonly comprises a simple ON/OFF air sensing thermostat (eg. Capstat or Durastat) acting through a load contactor if required, which fully powers the system at all times when the air temperature falls below a set point of say 4°C. The system may typically be energised for 2000 hours per year.

Circuit Health Monitoring

When self-regulating heaters are used, circuits may be monitored only for continuity. If monitoring for correct heating function is required, a constant power heater should be selected and used in conjunction with an automatic and continuous circuit health monitor and alarm (eg. Monitohm or Watchdog).