Internal Pipe Tracing

The Problem

Internal heat tracing is used to internally heat pipes where external tracing is impractical. Such situations may include:

- buried pipes

- sections under roads

- pipes in ducts

- submerged pipes

- inaccessable pipework

- pipes with existing insulation

Pipework may typically contain fuel oil or other fluids.

The Solution

Intertrace

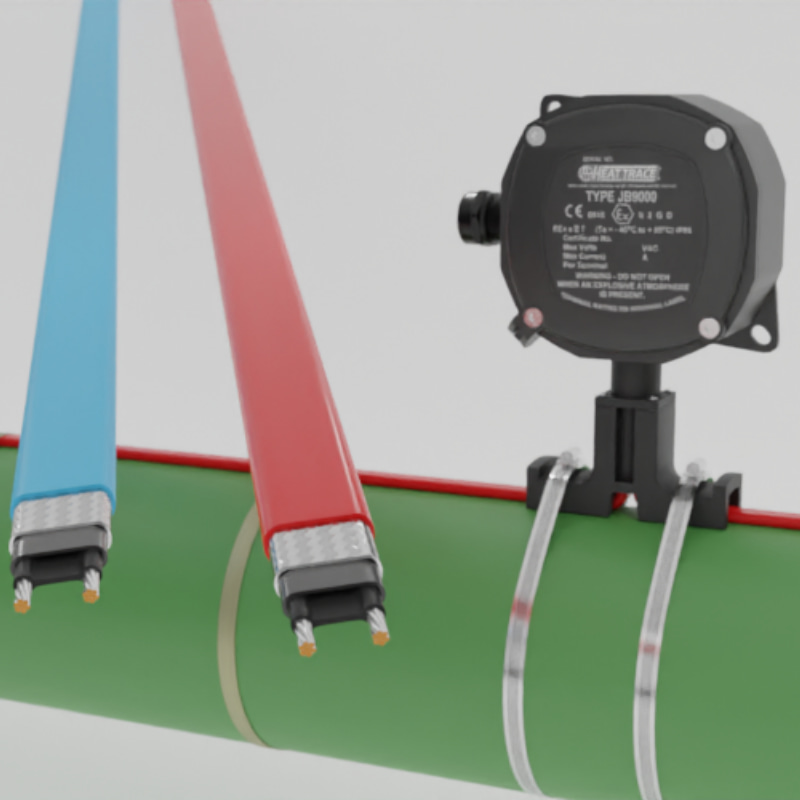

Heat Trace manufacture and supply a complete system which may comprise:

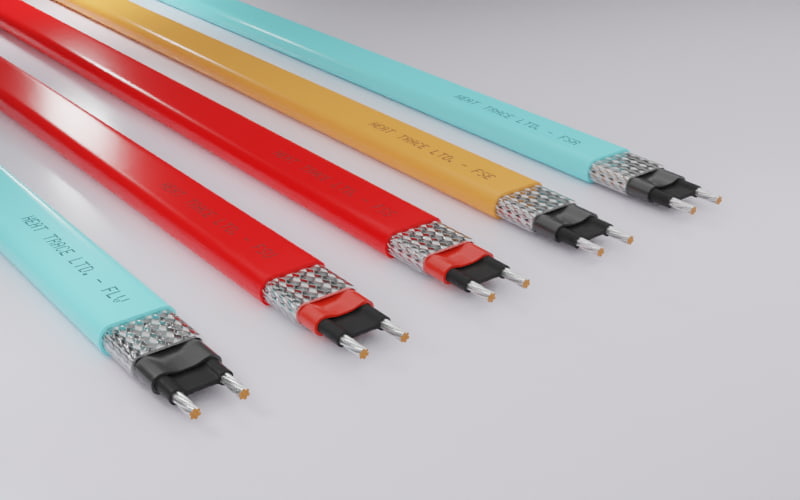

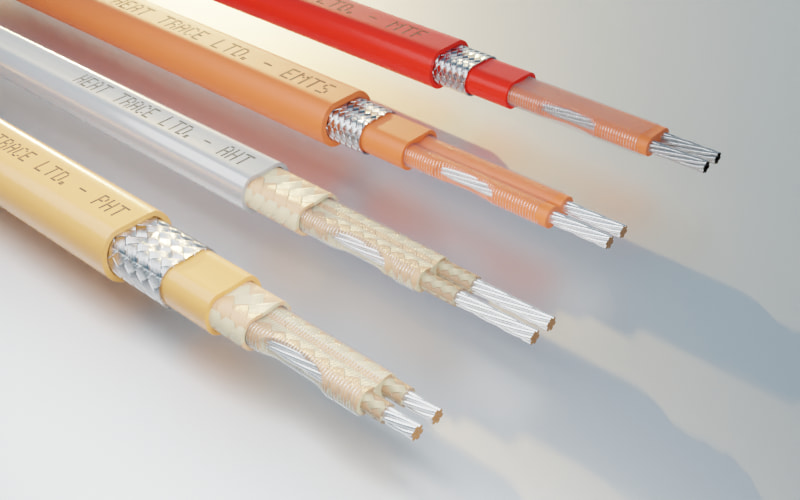

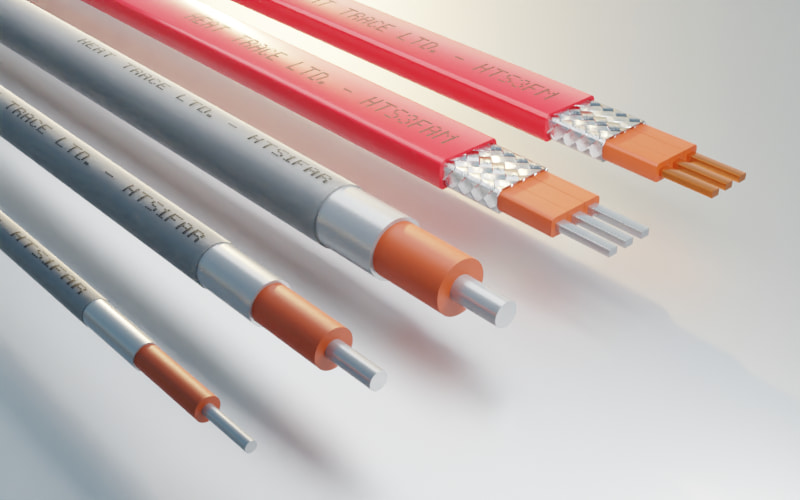

- heating circuits, metal sheathed, mineral insulated

- fabricated stub pipes for exiting heating cables

- junction boxes for power, series or star point connections

- temperature controls; either capillary or solid state

- control panels

- thermal insulation (where appropriate)

See photos (right) - Installation of Intertrace for Mobil, Australia

View the Heat Trace Cable Range Max Exposure Temperature & Output Capability Graph:

Design

Heat Trace design the system so that the heating load attains the desired pipe temperature. Loads are calculated to take account of losses from pipes which may be buried in soil/sand etc, surrounded by air, or submerged in water. In the latter case, a closed cell insulation system will almost certainly be required, whilst insulation may also be necessary, or desired, for open pipework. Cables are rated so that they operate at safe temperatures. Sheath materials are selected to be chemically resistant to the fluid in which they are immersed. Cables may be single or multiple runs arranged for single or three phase connections.